● Greatly improvements in Size precision,Flatness and Circularity of resin mold product

● High quality of the surface smoothness and the micro reinforcement greatley improved the abrasion-resistant

● Excellent performance of the electrification prevention, the static diffusion and the attenuation has been achieved

● Unique Superior performance of Resin compound has been acieved by the highest level technology for forming composite materials

Grade

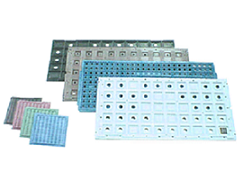

【Metal-Substitute, Precision Molding Grade】

● Low shrinkage rate and high liquidity make a significant contribution to high performance of precision molding.

● By the effects of material anisotropy on impact mitigation in molding, the flatness, the circularity are greatly improved and prevents warpage.

【Sliding and Abrasion-resistant Resin Grade】

● Low friction coefficient has been achieved by the excellet surface smoothness.

● Abrasion-resistant performance has been greatly improved by compounding of "AMTETRA".

【Antistatic, Conductive Resin Grade】

● Maintain highest level performance of antistatic and conductivity stably.

● Excellent performance of static diffusion.

【Electromagnetic Radiation Shield Resin Grade】

● By adopting Special Conductive Filler, it provides excellent shielding performance of an electromagnetic.

● Excellent Stable performance of moiding and surface condition has been achieved.

| Function | Grade | Base Resin | Features | Use Example |

|---|---|---|---|---|

| Metal-Substitute, Precision Molding |

MD15S | PPS | High rigidity / Size stability / Heatproof | component of hot water dispenser |

| MD401C | PPS | High rigidity / High Sliding / Conductivity / Heatproof | Servo motor case | |

| MD102 | PPS | High rigidity / Low specific gravity / Conductivity / Heatproof | Gear pump | |

| Sliding and Abrasion-resistant | MO10B | POM | High Sliding / Abrasion resistance | Precise gear |

| MN20K66 | PA | High Sliding / Abrasion resistance | Precise gear | |

| Antistatic, Conductive | MP20A | PP | Conductivity / Size stability [Carbon compound materials] |

Tray for IC |

| MB10A | ABS | Antistatic / Extrusion Processing [Non-carbon materials] |

Tray for liquid crystal Hairbrush |

|

| MB10AN | ABS | Antistatic / Extrusion Processing [Non-carbon materials] |

Tray for liquid crystal | |

| Electromagnetic Radiation Shield | EC-100 | ABS | EMI Shield / substituting metal [Carbon Fiber Composite] |

Shield Case (PH measurement) |

| EC-400 | ABS/PC | EMI Shield / substituting metal [Carbon Fiber Composite] |

Shield Case (component of motor) |

*Available for custom manufacturing, like a kind of masterbatch, etc.

Compared with mold shrinkage and warp of plate

| AMTETRA(wt%) | Glass fiber(wt%) | Compared with mold shrinkage(TD/MD) | Warp of plate(%) |

|---|---|---|---|

| 0 | 30 | 5.5 | 35 |

| 10 | 30 | 4.2 | 23 |

| 20 | 30 | 3.8 | 18 |

| 30 | 30 | 2.5 | 15 |

Surface smoothness of resin mold product

1.PC resin / AMTETRA / Glass fiber compound

| AMTETRA | Glass fiber | Average surface rouhness(Ra) |

|---|---|---|

| 0wt% | 30wt% | 6.5μm |

| 10wt% | 30wt% | 3.2μm |

| 20wt% | 30wt% | 2.0μm |

Measuring sample :Plate of PC resin(100×100×3mm)

Measuring speed :0.6mm/min

Measuring direction :Perpendicular to the gate

Measuring length :100mm

2.PPS resin / AMTETRA / Glass fiber compound

| (μm) | |||

| AMTETRA | Glass fiber(GF) | Average surface rouhness(Ra) | Maximum peak height(Ry) |

|---|---|---|---|

| 0wt% | 30wt% | 1.27 | 14.3 |

| 10wt% | 30wt% | 1.14 | 13.1 |

| 20wt% | 30wt% | 0.97 | 11.5 |

| 30wt% | 30wt% | 0.94 | 10.8 |

The measurement method and the conditions of measurement sample, measurement condition, and measurement length are the same as those of PC resin.

3.LCP resin / AMTETRA / Glass fiber compound

| (μm) | ||

| AMTETRA | Glass fiber(GF) | Average surface rouhness(Ra) |

|---|---|---|

| 0wt% | 30wt% | 1.45 |

| 15wt% | 30wt% | 0.62 |

Weld Improvement Effect

When a weld-line is generated by a colliding mass of flowing resin during molding, AMTETRA composite resin delivers greater weld-line improvement effects when compared to talc-composite resin.

Visual evaluation: Talc-composite resin is characterized by a dark shaded area near the weld-line; however, AMTETRA composite resin showed almost no change of color.

Comparison of weld-line height and width:・AMTETRA composite : Height 3 μm, Width 10 μm

・Talc composite : Height 10 μm, Width 32 μm

1.AMTETRA Composite Conductive PPS Resin Motor Component Material

Required characteristics for AC servomotor rotary encoder cover resin・Electromagnetic shield performance (Conductivity)

・Heat resistance (High heat deformation temperature)

・Toughness (High bending elasticity)

・Flame retardation (94V-0)

・Environmental resistance (Dimensional stability, Low linear expansion coefficient)

【Features】| Test item | Unit | Representative property value |

|---|---|---|

| Specific gravity | 2.0 | |

| Tensile strength | MPa | 170 |

| Tensile elongation | % | 1.5 |

| Bending strength | MPa | 225 |

| Bending elasticity | GPa | 14.7 |

| Izod impact value | J/m | 39 |

| HDT | ℃ | >260 |

| Molding shrink rate(%) | MD | 0.3 |

| TD | 0.5 | |

| Linear expansion coefficient(%) | MD | 2.1×10-5 |

| TD | 2.5×10-5 | |

| Surface resistance value | Ω | 103~5 |

2.AMTETRA Composite PPS Resin Water Heater Component Material

【Resin features】・High rigidity

・Environmental dimensional stability

・Low warping

High rigidity grade with excellent dimensional stability and ultra-precision molding performance

| Measurement item | Unit | Representative property value |

|---|---|---|

| Tensile strength | MPa | 110 |

| Bending strength | MPa | 160 |

| Izod strength | J/m | 59 |

| Bending elasticity | GPa | 19.6 |

| HDT | ℃ | >260 |

| Linear expansion coeffcient(%) | MD | 1.9×10-5 |

| TD | 2.2×10-5 |

● property・・・・・grainy(pellet)

● Packing Form・・・25kg /paper Bag